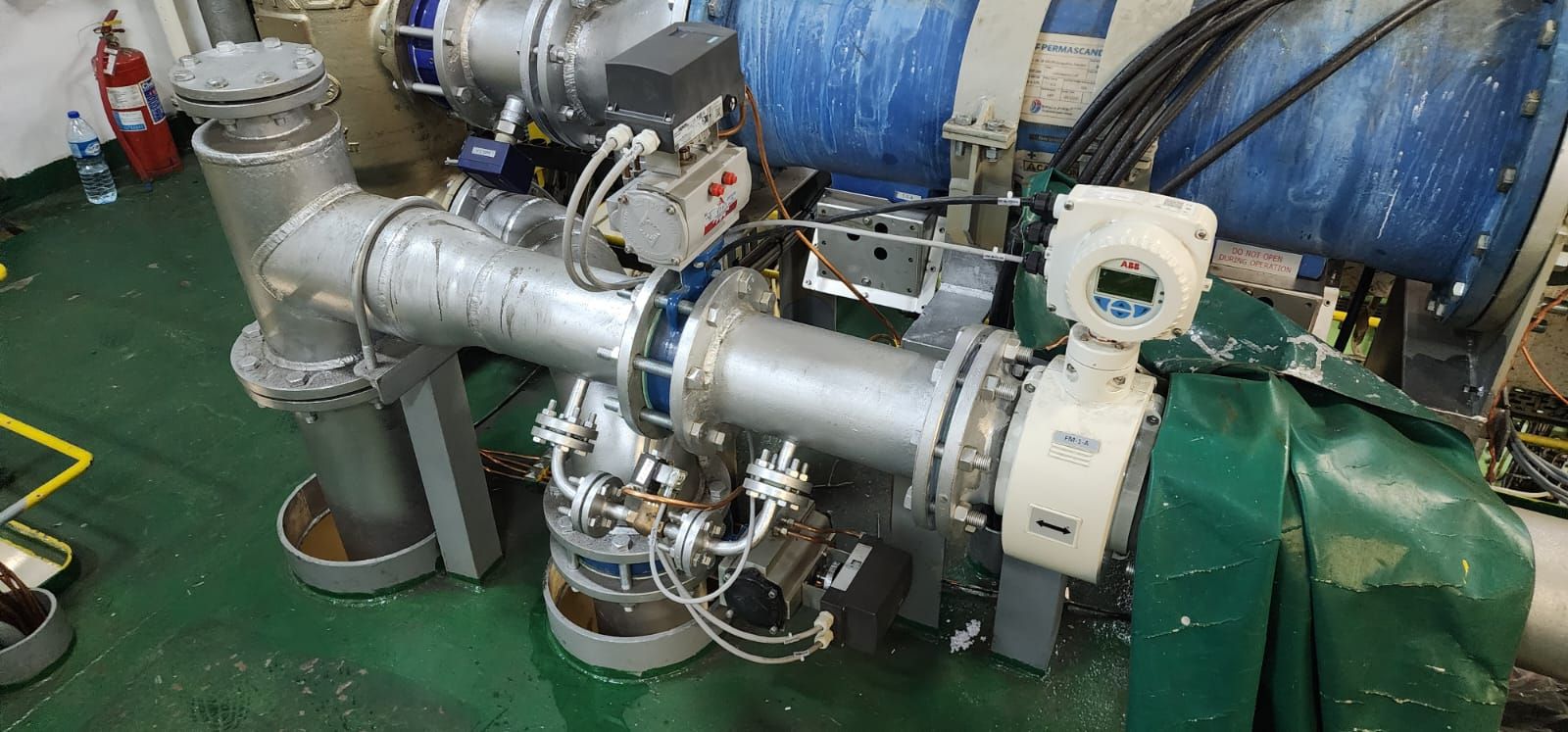

BWTS INSTALLATION

Operational Efficiency: Installing BWTS without halting ship operations minimizes downtime. Stopping at a shipyard can be costly and time-consuming. By performing the installation while the ship is underway, operators can maintain their schedules and avoid disruptions to their shipping routes and delivery timelines.

Cost Savings: Shipyard services and dry docking are expensive. In-situ installation of BWTS reduces the need for these costly procedures. Additionally, it avoids the loss of revenue associated with taking the ship out of service for an extended period.

Environmental Protection: Properly treating ballast water prevents the spread of harmful aquatic organisms and pathogens. This protects marine ecosystems and biodiversity, which is crucial for maintaining the health of the oceans and complying with environmental standards.

Flexibility: Performing the installation while the ship is at sea or during routine operations allows for greater scheduling flexibility. It eliminates the need to coordinate with shipyard availability and can be planned to minimize impact on the ship’s operational commitments.

Improved Vessel Value: Having a BWTS installed enhances the vessel's market value and competitiveness. Ships equipped with compliant systems are more attractive to charterers and can access a wider range of ports without restrictions.

Process of BWTS Installation While Ship is in Operation

Planning and Design: Detailed planning is crucial. This involves selecting a suitable BWTS, designing the installation process to fit the ship's layout, and ensuring all necessary components are available.

Pre-fabrication: Wherever possible, components are pre-fabricated to minimize the amount of work needed onboard. This includes pipe spools, supports, and other assemblies that can be quickly fitted into place.

Onboard Survey and Preparation: Before installation, a survey is conducted to understand the exact requirements and prepare the ship. This includes identifying locations for equipment and routing for pipes and cables.

Installation Team: A skilled installation team, often including specialists from the BWTS manufacturer, boards the ship. This team is experienced in working under the unique conditions of an operational vessel.

Installation Work: The actual installation is carried out in phases to avoid disrupting the ship's operations. This might involve installing components during calm weather or when the ship is in port for short periods.

Integration and Testing: After installation, the BWTS is integrated with the ship’s existing systems. Thorough testing is conducted to ensure that the system operates correctly and meets regulatory requirements.

Crew Training: Training the crew on the operation and maintenance of the new BWTS is essential for ensuring its effectiveness and compliance with regulations.

By installing BWTS while the ship is operational, ship owners and operators can meet regulatory requirements efficiently, reduce costs, and protect the marine environment without compromising their operational schedules.

.jpg)